What is HAZOP?

HAZOP (Hazard and Operability Study) is a method used to identify risk scenarios linked to operational processes and steps. Risk analysis aims to find situations that should not happen in the process stages, and consequently, bring risks to people, equipment, and the environment. It is essential to previously analyze the P&ID (Piping & Instruments Diagram) to be studied in order to define the "nodes" that will be the object of the HAZOP study.

How does HAZOP work?

The Technik group has specialists to train the multidisciplinary team for the study in a series of meetings, in which it performs the application of guide words to the process variables.

The first step for the application consists of the selection of a process node, that is, the mapping of a process.

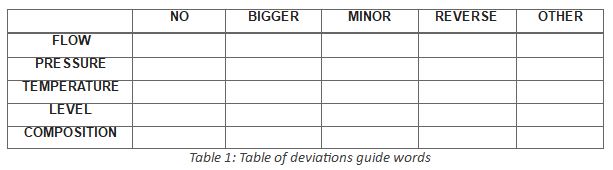

The combinations between guide words and variables refer to the deviations in the table below that may occur in the variables throughout the production process.

With the defined combinations, it is necessary to define the safeguards used for the prevention and containment of the causes and consequences of deviations: Humans, Control, interlocks, and safety devices.

Risk Determination

It is necessary to study the topic after to determining the guide word and a variable to specify each possible scenario in the process.

As said before, the 2 combinations identify the scenario and all the effects that caused the deviation, and likewise, the relevant factors that prevent problems, also known as safeguards. These safeguards can be all possible solutions to avoid the effects, such as instruments, operators in the area, training, and others.

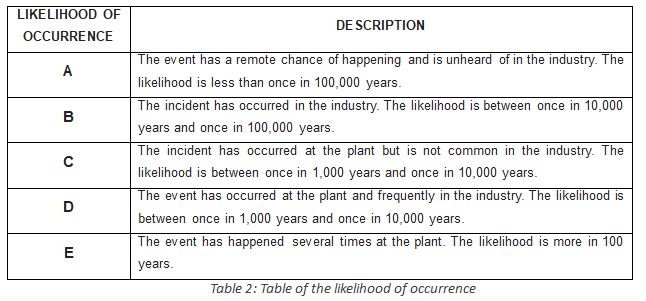

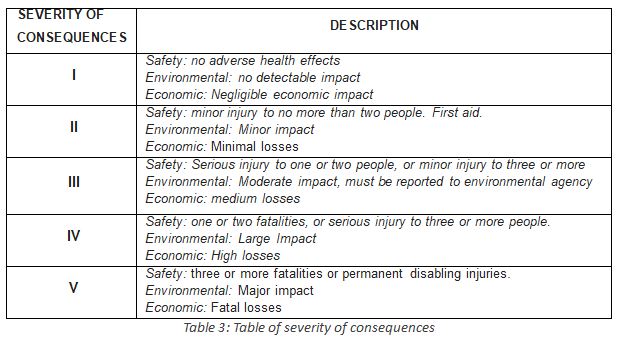

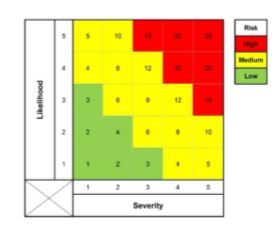

In a company with a multidisciplinary team, the classifications are made using the two tables below to identify the likelihood of occurrence with which the analyzed scenario can happen and the degree of severity of consequences.

The two tables together form another table, which determines the risk matrix.

Table 4: Risk Matrix

The risks must be greater than medium (number 3 and yellow) for the multidisciplinary team to find the suggested actions for risk reduction, and recategorize the risk classification according to the new recommendations.

Application Example

Let's take a look at a real example that has been adapted for even clearer content.

In a company when determining a "node" as compressed air, in which the chosen variable was the "pressure" and the guide word applied was "lower," the result in the deviation "lower pressure" was raised to a failure of the pressure regulator filter or improper valve closure upstream of the compressed air vessel. Consequently, the pump could cause internal wear, excessive noise, vibration, and damage to the vessel. That is, in case of continuing operating with a lack of flow on the line.

From this, it is determined to safeguard them as operational training, detectors, and alarms with indications of failure and interlocks that prevent future problems from happening.

What is the importance of HAZOP?

Analyzing the risks of the process is of extreme value for its proper functioning and, consequently, can generate a number of advantages for the organization.

Controlling deviations can keep variables within specifications and optimum product quality.

Quickly

Quickly