New Delhi [India], September 13 (ANI): Researchers at the International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), an autonomous R&D centre under the Department of Science and Technology, has developed nanosecond laser surface texturing, which promises to improve lubrication within internal combustion (IC) engines and address the challenge of friction and wear between moving parts.

According to the Ministry of Science and Technology, internal combustion engines, a cornerstone of modern transportation with millions of vehicles operating globally, face persistent issues with efficiency, primarily due to energy loss from friction and wear.

A substantial portion of the energy supplied to these engines is lost through thermal and frictional dissipation, with frictional losses in the piston-cylinder system reaching nearly 50 per cent.

Notably, 70 per cent-80 per cent of these losses occur in the piston rings, highlighting the critical need for improved tribological performance--an area of study focussing on friction, wear, and lubrication.

Also Read | Floods in Europe Caused by Vb Conditions. What Are They?.

To tackle this, ARCI researchers have introduced nanosecond laser surface texturing. This technique uses lasers with a 100 nanosecond pulse duration and a wavelength of 527 nanometres to create precise surface textures on gray cast iron components such as piston rings and cylinder liners.

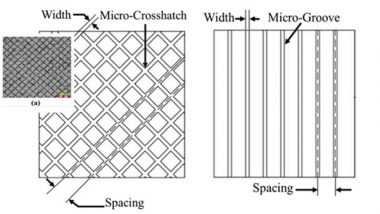

The method produces micro-textures, including micro-grooves and micro-crosshatch patterns, which enhance lubrication by acting as reservoirs for lubricants, trapping wear debris, and improving hydrodynamic lubrication.

Traditional surface texturing methods like vibe rolling, abrasive machining, and chemical etching often result in non-uniform patterns and inconsistent tribological performance.

In contrast, nanosecond laser surface texturing provides superior control over the texture shape and size, resulting in more reliable and reproducible outcomes.

The technology has demonstrated significant improvements in friction reduction and wear resistance through rigorous tribological tests conducted using a ball-on-disc tribometer, which simulates sliding contact between surfaces.

The benefits of this technology extend beyond internal combustion engines. By reducing friction and wear, nanosecond laser surface texturing has the potential to enhance performance across various industries, including automotive and manufacturing.

The cost-effectiveness of the nanosecond laser method makes it a practical solution for industrial applications, paving the way for more efficient, sustainable, and cost-effective solutions in friction and wear management. (ANI)

(This is an unedited and auto-generated story from Syndicated News feed, LatestLY Staff may not have modified or edited the content body)

Quickly

Quickly